VORTEX TUBES, COOLING / HEATING WITH COMPRESSED AIR

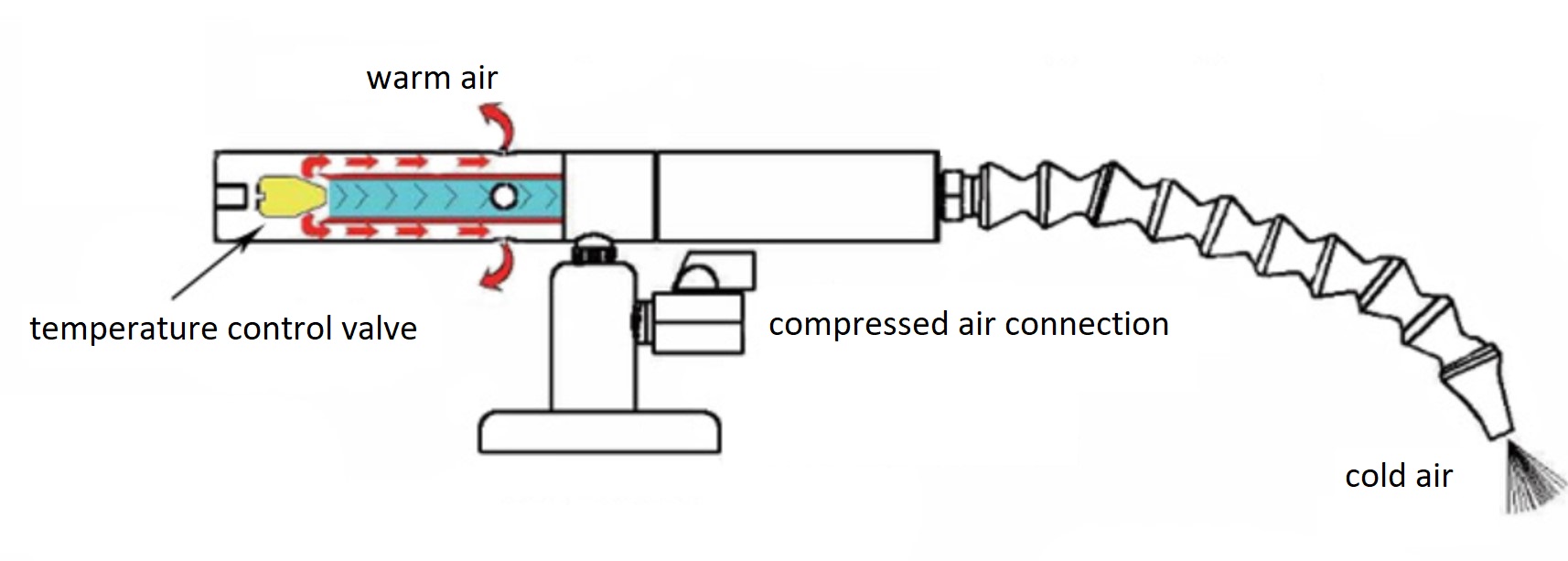

Principle of Vortex tubes

Vortex tubes are used in thousands of industrial applications for cooling or heating employing compressed air as the source of power. A vortex tube distributes compressed air from the system in two air flows: one hot and one cold. This way it achieves temperatures ranging between -46 °C and +120 °C using merely filtered compressed air.

Compressed air enters tangentially a generator (where it can even achieve the speed of sound) that makes the air rotate through the tube alongside the internal wall toward the hot control valve at up to 1,000,000 rev./min.

Part of this air comes out through the throttle valve out of the tube as a hot stream. The remaining air is pushed back through the middle of the airflow where a simple (natural) heat exchange occurs. The internal, more slowly moving, air column transmits the heat to the external, faster moving airflow. The slower internal airflow then comes out through a cold exhaust where it achieves extremely low temperature.

.

Vortex tubes – pneumatic cooling

Vortex tubes for general cooling and heating with compressed air as the source of power.

Application:

- Cooling and heating of products

- Cooling of machines and devices

- Cooling during soldering, welding, etc.

- Cooling of electronics

- Cooling of gas and liquids

- Protective cooling of cameras and sensors

- And others

Advantages:

- No movable parts – reliable maintenance free

- No coolant

- No risk of sparking or explosion

- Compact and lightweight design, low price of application

- Immediate cold/hot air

Vortex tubes – tool cooling

The compact design of the vortex tube in a set with a link plastic tube for directing the cold airflow to the required place, e.g. a cooled turning machine, textile needle, etc.

It can be used on a magnetic platform allowing simple installation on machines.

Vortex tubes – switchboard cooling

Compact vortex tubes designed for cooling industrial cases – technological switchboards.

main advantages:

- no electricity is needed, just compressed air is enough

- low noise, high reliability and efficiency

- the device is unattended and maintenance-free

- easy and fast installation

Comprehensive solution for switchboard cooling: the set contains a vortex tube, thermostatic device and a hose for air distribution in the switchboard.